ZnS wurtzite ceramic fabrication by a simple and cost‐effective pressureless sintering method: A microstructure development overview

Accepted: 5 July 2020

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

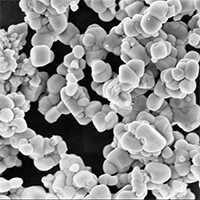

The Two-Step Sintering (TSS) process is a useful method to obtain sintered materials of high density and to limit the grain growth associated with the final stage of the sintering process. One of the main advantages of this method is the lowering of the sintering temperature. The development of bulk, dense and small grain size in the wurtzite phase of the ZnS ceramic was investigated by using a micron-sized ZnS powder as a precursor material. The microstructure and morphology of the TSS-fabricated ZnS ceramic pellets were observed by Scanning Electron Microscopy (SEM) and compared to those produced by the conventional sintering process. The ZnS ceramic produced using the TSS method at 1100°C showed comparable density and a much finer microstructure (five times smaller grain size) than the ZnS ceramic produced using conventional sintering at 1250°C. It was demonstrated that the TSS process is a pressureless, simple and cost‐effective sintering method, able to deliver high density bulk, wurtzite phase ZnS ceramics with controlled grain size.

Supporting Agencies

European Union’s Horizon 2020 Research and Innovation Programme under the Marie Skłodowska-Curie grant, Piano triennale di realizzazione 2019-2021 della ricerca di sistema elettrico nazionale – Progetto 1.3 Materiali di frontiera per usi energeticiPAGEPress has chosen to apply the Creative Commons Attribution NonCommercial 4.0 International License (CC BY-NC 4.0) to all manuscripts to be published.

An Open Access Publication is one that meets the following two conditions:

- the author(s) and copyright holder(s) grant(s) to all users a free, irrevocable, worldwide, perpetual right of access to, and a license to copy, use, distribute, transmit and display the work publicly and to make and distribute derivative works, in any digital medium for any responsible purpose, subject to proper attribution of authorship, as well as the right to make small numbers of printed copies for their personal use.

- a complete version of the work and all supplemental materials, including a copy of the permission as stated above, in a suitable standard electronic format is deposited immediately upon initial publication in at least one online repository that is supported by an academic institution, scholarly society, government agency, or other well-established organization that seeks to enable open access, unrestricted distribution, interoperability, and long-term archiving.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

https://doi.org/10.4081/microscopie.2020.9203

https://doi.org/10.4081/microscopie.2020.9203