ZnS wurtzite ceramic fabrication by a simple and cost‐effective pressureless sintering method: A microstructure development overview

Smart Citations

Smart CitationsSee how this article has been cited at scite.ai

scite shows how a scientific paper has been cited by providing the context of the citation, a classification describing whether it supports, mentions, or contrasts the cited claim, and a label indicating in which section the citation was made.

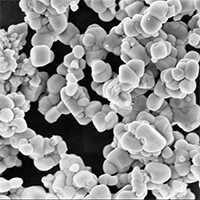

The Two-Step Sintering (TSS) process is a useful method to obtain sintered materials of high density and to limit the grain growth associated with the final stage of the sintering process. One of the main advantages of this method is the lowering of the sintering temperature. The development of bulk, dense and small grain size in the wurtzite phase of the ZnS ceramic was investigated by using a micron-sized ZnS powder as a precursor material. The microstructure and morphology of the TSS-fabricated ZnS ceramic pellets were observed by Scanning Electron Microscopy (SEM) and compared to those produced by the conventional sintering process. The ZnS ceramic produced using the TSS method at 1100°C showed comparable density and a much finer microstructure (five times smaller grain size) than the ZnS ceramic produced using conventional sintering at 1250°C. It was demonstrated that the TSS process is a pressureless, simple and cost‐effective sintering method, able to deliver high density bulk, wurtzite phase ZnS ceramics with controlled grain size.

https://doi.org/10.4081/microscopie.2020.9203

https://doi.org/10.4081/microscopie.2020.9203